An Essential Guide to Cement

Whether knowingly or not, you’ll have come across cement at every stage of life, from where you were born, to the school you attended, a holiday you took or the house you live in. Cement, in various forms, can be traced back to the very beginnings of human civilisation and is a crucial component of the built environment. Often confused with concrete, our guide reveals what cement is, how it’s used in construction and the different types available…

Summary of key points:

- Cement is a binding agent used in construction that sets and hardens quickly.

- Cement's primary use is as an ingredient for concrete, which is used worldwide in construction projects, from essential services to major infrastructure.

- Cement is made of a combination of limestone or chalk, clay or shale, and smaller quantities of materials like sand, iron or bauxite.

- Cement can be categorized into two types: hydraulic and non-hydraulic based on the way it sets and hardens.

- Portland cement is the most popular version of hydraulic cement.

- Cement is used in construction because of its versatility, making it a popular choice for domestic and industrial construction projects.

What is cement?

Cement is one of the most commonly used materials in building and is essentially a binding agent to hold other materials together. It sets and hardens quickly, meaning it can support a lot of weight without changing shape. Cement is one of the core components of concrete.

What is it used for?

Cement’s primary use is as an ingredient for concrete, which is used worldwide in construction projects, from essential services such as schools and hospitals to major infrastructure including airports, bridges and motorways.

Other uses for cement include to seal fractures, for soil stabilisation and on decorative projects such as fencing, patios and driveways.

What is cement made of?

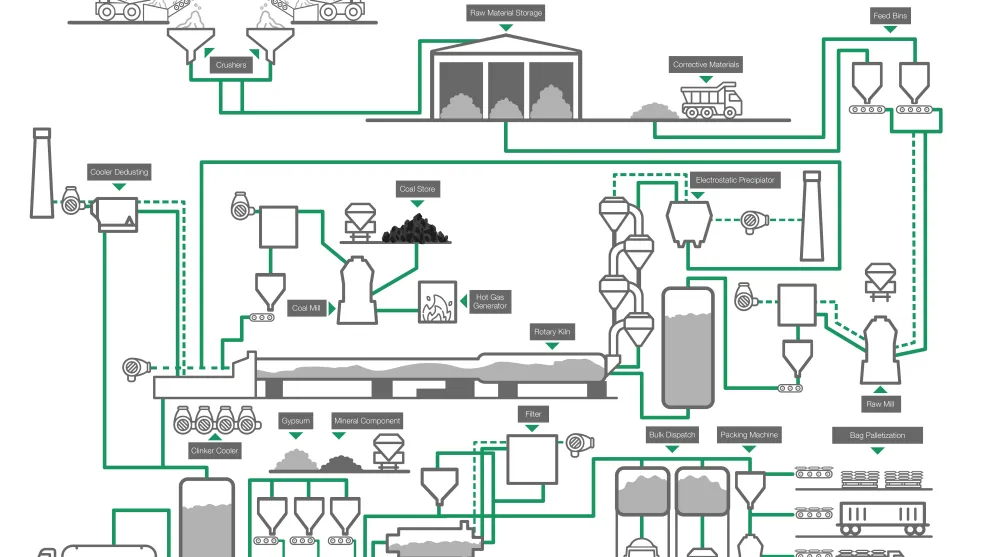

Cement comprises a few materials. The main material constituents are limestone or chalk followed by clay or shale. Most of the time, some other materials are required in smaller quantities (minor constituents, also called correctives) to adjust the combined chemical composition. Minor constituents typically are sand, iron or bauxite. The blend of these materials is ground and heated at high temperatures in a kiln. This makes a rock-like substance (called "clinker") which is then ground into the fine powder that we know as cement.

The different types of cement

Cement can be categorised into two types; hydraulic and non-hydraulic based on the way it sets and hardens.

Hydraulic

Hydraulic cement is the most commonly used variation and hardens due to the addition of water. This makes it an ideal material for the built environment, as it’s easy to apply (even in wet conditions) and due to its rapid drying characteristics, makes it favourable for use on outdoor construction sites. Portland cement is the most popular type of hydraulic cement.

Non-Hydraulic

Less practical than its hydraulic counterpart, non-hydraulic cement hardens when it comes into contact with carbon dioxide in the air. This means it cannot be used in wet conditions or underwater, and can also take up to a month before it’s completely hardened and able to be used. For indoor stonework or mortar use, it’s still a popular choice. As the construction industry looks to reduce its carbon footprint, more sustainable alternatives to cement are becoming available. These include:

- Fly-ash - a by-product of coal fired power plants that would otherwise go to landfill, fly-ash can be mixed with cement and water to improve the durability and workability of the concrete.

- Ground Granulated Blastfurnace Slag (GGBS) – a by-product of iron blastfurnaces, GGBS is used as a supplementary cementitious material to improve concrete durability, reduce heat of hydration and embedded CO2.

- Natural pozzolans and calcined clays – natural pozzolans are sourced from natural mineral and volcanic deposits, while heat treatment of some specific clays can transform them into pozzolans

- Secondary materials such as crushed recycled concrete, aggregates and recycled glass

What is the difference between cement and concrete?

Cement and concrete are often used interchangeably, but they are two different things. Cement is the main binding agent for concrete. Concrete is made from a mix of cement, water and aggregates (e.g. sand, gravel, crushed stone) and is the most widely used manufactured material on the planet.

Why is cement used in construction?

Cement is extremely versatile, making it a popular choice for domestic and industrial construction projects. Portland cement is the most widely used and the reasons for this are:

- It can be used to bind mortar, render or concrete

- It is highly durable, meaning it can add strength to structural elements and withstand compressed loads

- It sets quickly, underwater and in wet conditions

- It is low maintenance, making repairs less likely and therefore projects more cost- effective

- It is available in grey and white, enabling different aesthetics and reducing street lighting requirements, due to the reflective nature of the final surface finish.

Conclusion

Cement is undoubtedly the backbone of the construction sector and has been a fundamental component of our buildings and infrastructure for thousands of years. Versatile, durable and reliable, it will continue to evolve to incorporate greener products and processes that satisfy a global demand.

Cement Drying Process

Frequently Asked Questions

Cement has a multitude of uses during construction and engineering including:

- To produce concrete for all applications

- To produce mortar for plastering, masonry, pointing

- Water tightness

- Preparing foundations

- Manufacture precast pipes, fittings and joints

- Grouting

- Aesthetic architectural detailing

Typically, bulk cement is transported and delivered in specialist vehicles for high volume

usage. Bulk cement is manufactured in a range of products to suit different construction

requirements e.g. speed, strength, sustainability, architectural, and can be used on its own or

blended with other materials such as fly ash and GGBS.

Dry packed cement is an easy-to-use material that is available in water and tear resistant

bags for durability. Ideal for concreting, bricklaying, floor screeding and rendering, dry packed

cement is mixed on site with either sand, fine aggregate or water to achieve the product

needed for final application.

Cement production accounts for 8% of global CO2 emissions, largely due to the

manufacturing process. There is a worldwide effort to explore low carbon, more sustainable

alternatives such as fly ash, GGBS or microsilica, which make use of otherwise redundant

materials and are thought to reduce CO2 emissions by up to 80%, depending on the

technology used during manufacturing.

The cost of cement varies greatly depending on the type of cement and the region of the UK.

For consumers seeking smaller quantities of cement, we would recommend contacting local

stockists and merchants for their pricing.