Lytag concrete takes the load off stunning new London skyscraper

As the go-to concrete solution for building high rise structures, Aggregate Industries’ revolutionary Lytag product proved essential during the landmark development of 70 St Mary Axe – the latest skyscraper set to transform London’s skyline. The building is being developed by TH Real Estate and constructed by Mace to a design by Foggo Architects.

The Background

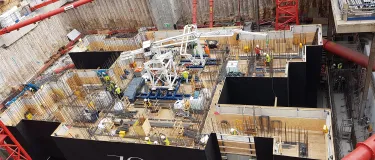

Neighbouring the legendary Gherkin tower, the £135m office development, known for its strikingly unique curved appearance, will offer 300,000 sq ft of prime office space at the heart of London’s business district. When completed later this year, the iconic structure will stand at an impressive 96 metres tall and 23 storeys high, with its unique shape specifically designed to allow for breathtaking views over the City.

The Problem

For concrete sub-contractors AJ Morrisroe, a key requirement of the project was to source a concrete solution that would enable larger floor spans to be cast without compromising the dead load of the overall structure. Key to ensuring that the building is constructed in an environmentally-friendly manner, it was also important that all materials were as sustainable as possible.

The Solution

The natural choice proved to be Lytag from Aggregate industries, a highly innovative lightweight concrete solution with unrivalled credentials when it comes to the construction of high rise structures. Up to 40% lighter than conventional concrete, during the development Lytag was able to effectively reduce the composite deck concrete slab load by approximately 25% over normal weight control, while offering the same level of structural performance.

Furthermore, as a concrete made from secondary aggregate, Lytag has unique properties that can help to significantly reduce the amount of natural quarried material required on a project – making it a much more environmentally friendly option than standard concrete.

In total, Aggregate Industries has supplied 2000m3 of Lytag to the project, which was instrumental in helping the tower recently receive an Excellent rating in BREEAM by conforming to clause WST 02 in relation to recycled aggregate.

What’s more, Aggregate Industries’ on-site inspector, who was present throughout the project, was always on hand to make sure the concrete pour ran smoothly and was successfully delivered on time.

Steve Curley, general manager for Lytag at Aggregate Industries, said: “As a modern skyscraper pushing the boundaries of construction and design, the 70 St Mary Axe project required equally innovative construction materials to achieve the building’s iconic vision. From the start it was clear there was no contender to Lytag and its unrivalled capabilities when it comes to building complex, high rise structures of this nature, especially for buildings looking to achieve a superior sustainable BREEAM rating.”

Anthony Blair, project manager at AJ Morrisroe said: “As one of the most high-profile developments in the Capital, it was important that the 70 St Mary Axe project used a sustainable concrete solution that would not only reduce the dead load bearing on the city’s foundation but also help the structure achieve its BREEAM targets.

For more information on Lytag call 01904 727922 or visit www.lytag.com

- Aggregate Industries lightens the load for 20 Old Bailey redevelopment - Case Study

- Lytag takes 100 Liverpool Street refurbishment to new heights - Case Study

- LytaScreed top of the class in £10m UCL revamp - Case Study

- Aggregate Industries keeps it light for high rise apartments - Case Study

- Woburn Golf Club stays on par with Sportag

Project details

-

Sector

High rise buildings

-

Architect

Foggo Architects

-

Client

TH Real Estate

-

Contractor

Mace

-

Sub contractor

AJ Morrisroe

-

Other information

- Highly innovative lightweight concrete solution

- Up to 40% lighter than conventional concrete

- Pushing the boundaries of construction and design

"We were delighted with the exceptional properties of Lytag, without which this project might not have been technically and architecturally possible. We were also impressed with the solution’s sustainable credentials and would like to thank Aggregate Industries for their excellent service, on-time deliveries and support throughout this development.”

The only UK based manufacturer of environmentally friendly, PFA based lightweight aggregate. Suitable for use in structural concrete, precast, fill, blocks, screed and drainage applications.