A14 Improvement Scheme, Cambridge to Huntingdon

Working with Balfour Beatty, Skanska and Costain, Aggregate Industries Expanded the A14 Huntingdon to Cambridge between 2016 and 2020.

The Brief

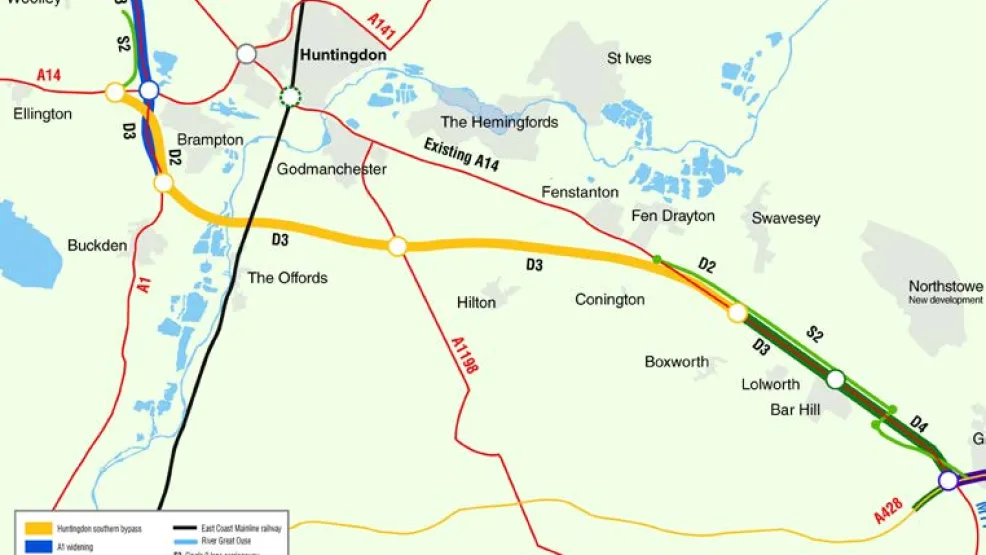

The A14 between Huntingdon and Cambridge is a strategically important part of the UK highway network; connecting Cambridge, Huntingdon and Peterborough to the A1 and M11 and is part of the A14 east/west route from the Midlands to the port of Felixstowe. Huntingdon to Cambridge has for many years been a major bottleneck, generating severe delays for commuters and goods. The £1.4 billion improvement scheme includes a 12 mile Huntingdon by-pass and additional carriageways to separate local traffic from through traffic. Additional lanes increase the existing highway capacity. The scheme also involved construction of numerous new bridges ad structures to integrate with the existing network. The works were planned to minimise disruption during construction.

The Solution

The A14 project was awarded as three separate contracts to two consortia. The contractors involved; Balfour Beatty, Skanska and Costain formed the A14 IDT (Integrated Delivery Team). To deliver the project it was split into six sections, each with a dedicated delivery team. The project was managed from three compounds located at Brampton at the northern end, Godmanchester in the centre and Swavesey to the south. The IDT brought the six management teams together into a single, highly effective, delivery model. Work on the scheme officially started in November 2016 and the new road was expected to open to traffic by the end of 2020. The main carriageway was fully reopened to traffic in April 2020 some eight months ahead of schedule.

The A14 IDT conducted a single procurement exercise for pavement construction covering all six sections and we successfully secured the main pavement contract for the whole of the project in competition with other major surfacing contractors. The assessment was 40% price, 40% quality and 20% behavioural. The behavioural element was assessed over a two-day process through observation of our ability to work easily with others along with our commitment and approach to collaboration. The IDT wanted to ensure that suppliers would be able to fit into the fully integrated team structure, with successful delivery of the project as the key driver rather than individual company objectives.

The complexity, time-scale and cost profile of the project demanded that collaboration was embedded right from the start. We attend weekly programme meetings to review progress and agree the future short-term programme; minimising conflict between activities and managing contract risk. Collaborative management tools include Touchplan, a cloud based lean planning tool, and ANDON, a new app based tool. ANDON provides a dashboard view of daily activity across all disciplines and is updated in real-time with input from supervisors using the app. Data, including non-productive time, is reviewed to see if any lessons can be learnt to improve efficiency.

The final design of the pavement is a composite of contract specific Cement Bound Granular Mixture (CBGM) sub-base and base layers overlaid with asphalt, all overlying a ground improvement layer (GIL) provided by others. A significant proportion of the surface course is low noise asphalt to minimise disturbance of local communities.

To deliver the 550,000 tonnes of CBGM we established three of our mobile continuous baching plants, one at each compound and one more than originally planned due to the increased use of CBGM. We also established a new, £3.5m asphalt plant at Godmanchester to deliver the 740,000 tonnes of asphalt required. Materials for CBGM were a mixture of site-won aggregates and stone from our Bardon Hill quarry and Pode Hole (St Neots). Imported material for CBGM and Asphalt was transported from Bardon Hill by rail to a North Cambridge railhead; it was then delivered to site by road. We had up to six of our pavers on site including two of our ABG Titan pavers dedicated to CBGM. Both of the CBGM pavers were equipped with Trimble PCS (Paver Control System) enabling direct input of the pavement design model and easy input of design changes. Trimble was also used to manage the asphalt surfacing process. Our “Right First Time” approach to quality has delivered the 1.29 million tonnes of pavement 99.9% defect free.

One of the key design objectives was limiting surface noise impacting on nearby villages and farms. We achieved this objective using our proprietary 10mm “SuperThin” surface course. This is the only HAPAS approved asphalt with a noise reduction rating of -7.8dB(A). In total we have laid over 34,000t of this material covering in excess of 25% of the new carriageway with one of the quietest surface courses available.

Health and Safety

We have an embedded safety culture supported from the very top through training and the involvement of senior management. All of our employees are empowered to question safety and to stop the job. This outstanding approach to health and safety has been recognised by the recent award of the new international standard ISO45001, Occupational Health and Safety Management Systems. As a result of our approach and commitment to health and safety we have completed over 400,000 working hours on the project with zero lost time incidents. We have managed risks such as 100,000 on-site vehicle movements delivering material to the pavers. We have carried out additional risk assessments and introduced new working practices to minimise and control the risk posed by Covid19 enabling us to work safely throughout the pandemic.

Our commitment to health and safety, collaboration and programme flexibility provided the IDT with key elements in their drive to achieve early completion. The use of CBGM on the early stages of the scheme demonstrated the benefits in terms of programme duration and flexibility to the extent that the use of these materials was extended to further sections of the project. Collaboration and integration extended all the way through to our internal and external supply chains resulting in exemplar levels of willingness to go the extra mile to deliver a successful scheme. We also had the resources available to service the project. To manage the risk posed by worker fatigue due to working two shifts a day, seven days a week, we called on our extensive internal resources and those of our supply chain to ensure safety at all times. We have had a maximum of 120 personnel on site and, in all, over 230 of our personnel have been involved in the project. This covers contracting, aggregates, asphalt, cementitious and wagon drivers.

More than Just a Road

The IDT has also been working hard to support local charities and good causes, with over 30 local projects sharing £280,000 to benefit around 2,000 people, as part of the A14 Community Fund. In addition around £60,000 has been raised for local charities through various initiatives. We have contributed to a number of events including the 2018 “Welly Walk” in aid of Cancer research; providing rollers and pavers for an unusual photo opportunity.

In support of the Rainbows Children’s Hospice Charity, Loughborough, we commissioned bespoke artwork for a new Titan paver that was stationed on the A14 to deliver the CBGM requirement. Rainbow’s is a long-term charity commitment for us that we support through fundraising and by raising awareness.

Awards

Our commitment to collaboration began before we commenced work on the A14 and continued right through to the end of our involvement. We have provided the IDT with a fully integrated pavement construction service. Our commitment has been recognised, firstly In December 2017 when during the first 360 KPI Review Meeting carried out by the A14 IDT our A14 team was commended for their ‘world class’ approach to collaborative behaviours.

Since that first accolade, our delivery team has worked hard to continually improve and strengthen existing collaborative relationships between the IDT and all supply chain partners on site. We were invited to join the IDT Main Board and, two years into the project, the commitment of our site team was further recognised at the 2019 A14 Supply Chain Leadership Forum & Awards event where we received the A14 Collaboration Award.

The collaborative nature of the contract was further recognised in 2018 when the whole of the IDT won the Supply Chain Award at the ICW (Institute of Collaborative Working) Collaborative Working Awards.

- Millbrook Road West resurfaced with low carbon SuperLow asphalt

- Aggregate Industries supports in creating the UK’s first ‘clean air’ substation

- Aggregate Industries offers green solution to A46 Warwick Bypass project

- Aggregate Industries’ roofing creates natural aesthetics for eco-friendly supermarket - Case Study

- Poundland distribution centre, Harlow

Project Details

-

Location

Huntingdon to Cambridge

-

Sector

Highways and Roads

-

Client

National Highways working with Balfour Beatty, Skanska and Costain

-

Products Used