Resurfacing Donington Park Race Track

Paving the way for the Future of Racing

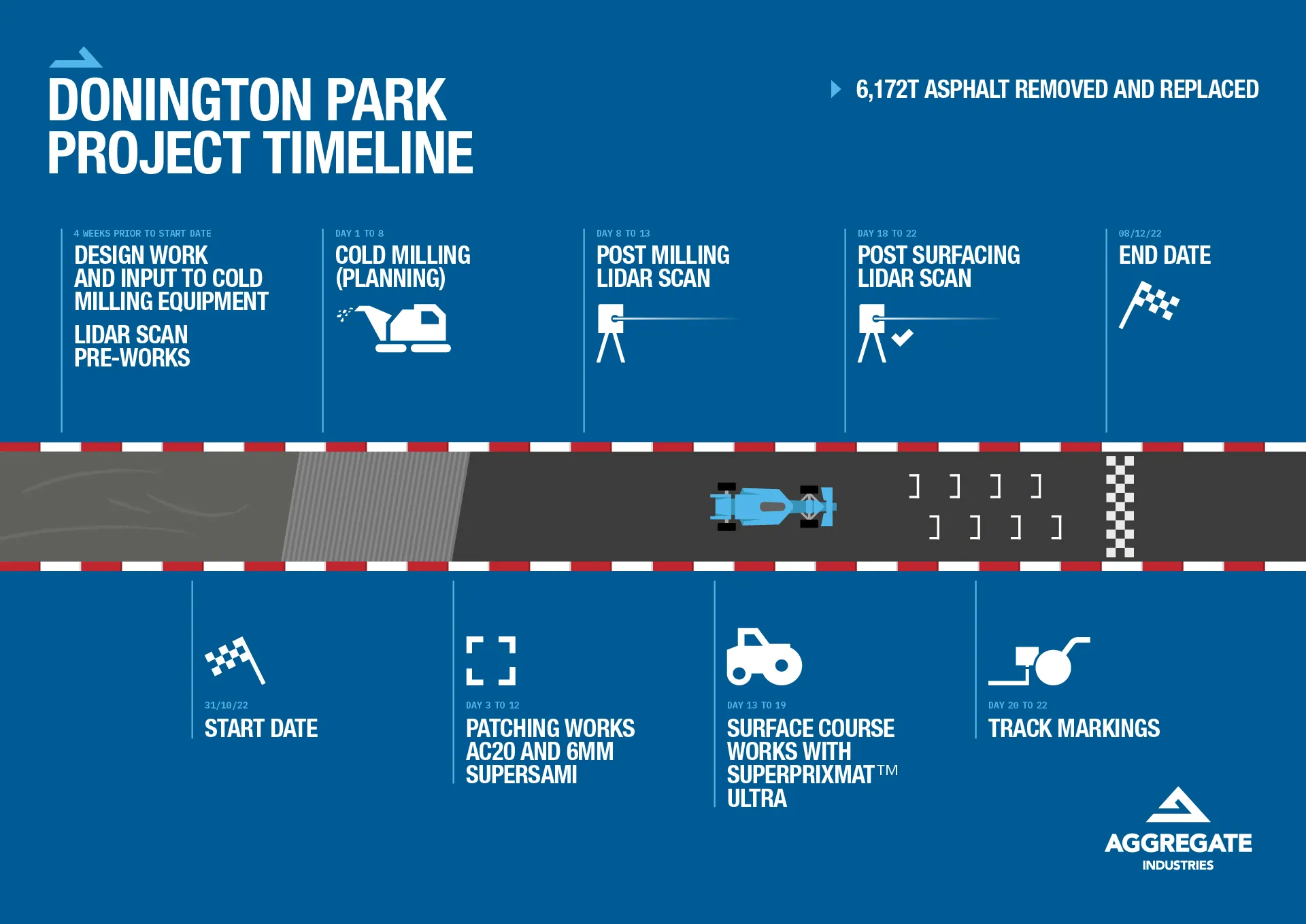

Collaborating with the client, MotorSport Vision (MSV) and the track designers, Driven International, we delivered a substantial upgrade to the world-renowned Donington Park race track. Over the course of an intensive 22-day schedule, our team removed and replaced more than 6,712 tonnes of asphalt, marking the most significant improvements at the venue in almost two decades.

The logistics of the operation were no less impressive. Over the 22 days, our dedicated team clocked in 10,710 hours of focused work. Despite the high-intensity environment and tight deadline, safety was never compromised - we're proud to report zero incidents during the project.

Innovation at the Core

Meeting the exacting requirements of a major project like Donington Park demanded innovation at every level.

Our approach started with optimizing supply chain logistics. With the help of our two closest supply plants - Bardon Hill & Tinsley - we ensured a continuous, uninterrupted supply of asphalt to the site. This allowed us to lay the product at a consistent speed in echelon to achieve a jointless surface, minimizing disruptions and maximising efficiency.

For the first time in the UK, we leveraged cutting-edge paving equipment from Wirtgen, including the S-2100-5i with extension boxes and MT3000-3i feeder pavers, and Multiplex Averaging beams.

Our onsite logistics coordinator ensured that the materials were laid in the order they were mixed, ensuring optimum temperatures and a constant flow of material

Using the Topcon Smoothride system on the Powerplane cold milling equipment resulted in maximum precision, achieving an average International Roughness Index (IRI) of 0.3, a third of the specified requirement.

We completed the project on time and within budget. This resurfacing marks the most significant improvements at the venue in nearly two decades, heralding a new era of high speed racing at Donington Park race track.

Discover why Aggregate Industries is the partner of choice for your next project.

Project Details

-

Location

Donington Park

-

Sector

Race Tracks

-

Client

-

PRoject Partners

-

Products Used

“The asphalt design and track requirements were very challenging and required the latest industry innovation to meet the design needs. An extremely tight ride profile was required to ensure a smooth ride was achieved around the track, together with an increased friction level”